Innovations in Biomedical Equipment Through Advanced PCB Assemblies

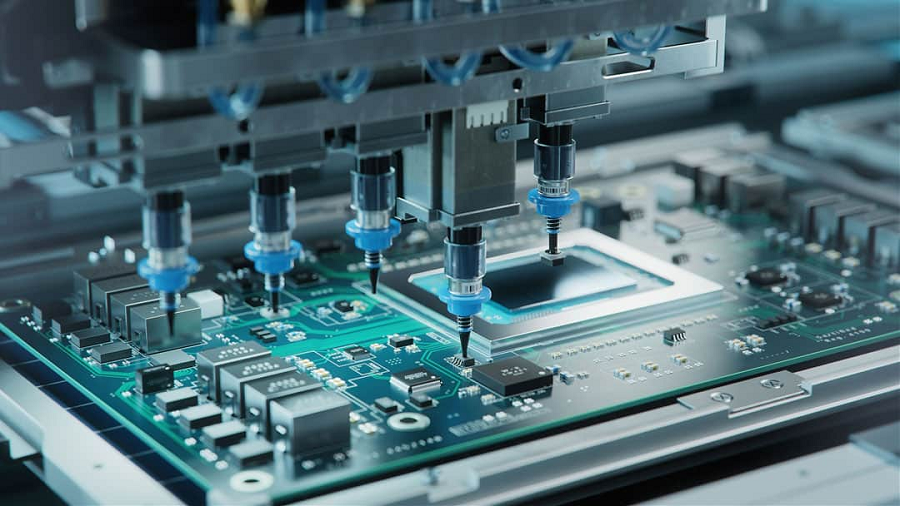

The biomedical equipment sector is a rapidly evolving landscape marked by the integration of cutting-edge technologies and innovations that push the boundaries of medical science. At the heart of many of these technological advancements are printed circuit board assemblies (PCBAs).

PCBAs are pivotal to the functionality, precision, and reliability of biomedical equipment, enabling the development of increasingly sophisticated medical devices that improve healthcare outcomes for patients around the world.

The Role of PCB Assemblies in Biomedical Innovations

Printed circuit board assemblies serve as the backbone of electronic medical devices, ensuring that components work seamlessly together. From imaging systems to diagnostic devices, PCBAs play a crucial role in facilitating accurate readings and reliable performance. These boards are designed to handle a wide variety of functions, including power distribution, signal transmission, and processing capabilities, all of which are essential for the medical field where reliability and accuracy can be the difference between life and death.

One of the main reasons PCBAs are crucial for biomedical devices is their ability to handle complex and precise tasks. The biomedical field often requires miniaturization of components, and advanced PCBAs are instrumental in meeting these needs. The trend towards more compact and portable medical devices necessitates smaller, high-density circuit boards that can still provide robust performance. Innovations in PCB design, such as multi-layered boards and surface mount technology (SMT), have enabled the creation of compact yet powerful devices like portable ultrasound machines, handheld diagnostic tools, and wearable health monitors.

Enhancing Diagnostic Accuracy and Patient Monitoring

PCB assemblies have revolutionized diagnostic equipment, allowing healthcare providers to detect and monitor health conditions more accurately and efficiently. Devices like magnetic resonance imaging (MRI) scanners, electrocardiograms (ECGs), and blood glucose monitors all rely on advanced PCBAs for their operation. High-quality PCBAs ensure that these devices can handle the massive amounts of data involved in scanning and diagnostics, thereby providing clear, precise results for healthcare professionals.

The integration of PCBAs in patient monitoring systems has also led to significant advancements in healthcare. Continuous patient monitoring devices, such as heart rate monitors, infusion pumps, and ventilators, utilize sophisticated PCB assemblies to track vital signs and deliver medication in real-time. These devices depend on reliable circuit boards that can operate continuously without fail. The advancements in PCB technology have made it possible for these devices to be more responsive, power-efficient, and capable of communicating with other devices in the healthcare network, providing doctors and nurses with critical patient data instantly.

Wearable Medical Devices and Point-of-Care Testing

One of the most significant trends in biomedical innovation is the rise of wearable medical devices and point-of-care testing (POCT) equipment. Wearable devices like smartwatches that monitor heart rate, blood oxygen levels, and even sleep patterns have transformed preventive healthcare by providing individuals with real-time insights into their health. These wearable devices are powered by compact and flexible PCB assemblies, designed to be lightweight, durable, and capable of integrating sensors and communication modules within a small form factor.

Point-of-care testing devices are also revolutionizing healthcare delivery by enabling rapid diagnosis at the patient’s location rather than in a centralized lab. Devices like portable blood analyzers and rapid diagnostic kits rely on PCBAs to execute complex biochemical analyses quickly and efficiently. PCBAs in these devices need to be highly reliable, as they are often used in critical scenarios where timely and accurate results are essential for patient care. Innovations in PCB design have allowed these devices to become more affordable, portable, and user-friendly, extending the reach of healthcare services to remote and underserved areas.

Reliability and Safety Standards in Biomedical PCB Assemblies

Reliability is paramount in biomedical equipment, where any failure could have serious consequences for patient health. PCB assemblies used in medical devices are therefore subject to stringent quality standards and regulatory requirements. The boards must undergo rigorous testing, including thermal cycling, humidity resistance, and vibration tests, to ensure they meet the necessary reliability and safety standards.

Advanced inspection techniques, such as Automated Optical Inspection (AOI) and X-Ray inspection, are crucial in ensuring that PCB assemblies used in biomedical devices are free from defects. These quality control measures help in detecting issues such as poor solder joints, misaligned components, or internal structural defects that could compromise the performance of the medical device. By adhering to strict quality standards, manufacturers ensure that medical devices can provide consistent and accurate performance throughout their lifecycle.

Future Trends in PCB Assemblies for Biomedical Applications

As the biomedical field continues to evolve, the role of PCB assemblies will only grow in importance. The trend towards personalized medicine is driving the development of devices that can be customized for individual patients, requiring PCB assemblies that are adaptable and capable of handling unique configurations. Flexible PCBs, for instance, are becoming more popular for use in wearable devices that must conform to the shape of the human body.

Another significant trend is the integration of Internet of Things (IoT) technology in medical devices. IoT-enabled medical devices can communicate with each other and with healthcare providers, creating a network of interconnected devices that can monitor patient health in real-time. PCB assemblies for IoT-enabled biomedical devices require advanced features such as wireless communication modules, sensors, and energy-efficient power management, all integrated into a compact design.

The use of artificial intelligence (AI) in medical diagnostics is also on the rise, necessitating PCB assemblies that can support high-speed data processing and machine learning algorithms. These boards must be designed to handle complex computations while maintaining energy efficiency, allowing AI-powered diagnostic tools to deliver accurate results quickly.

Conclusion

Printed circuit board assemblies are at the core of many of the most exciting innovations in biomedical equipment today. From enhancing the accuracy of diagnostic tools to enabling the development of wearable health monitors and point-of-care devices, advanced PCBAs are transforming healthcare delivery. As technology continues to advance, the role of PCB assemblies in biomedical applications will expand further, supporting the development of smarter, more personalized, and more interconnected medical devices that improve patient outcomes and revolutionize healthcare as we know it.